It's the size of a desk and can power 10,000 homes! Looks like there's a new renewable energy super hero in town...the 10 kilowatt watt supercritical carbon dioxide turbine!

As far back as 2012 there were rumors of a carbon dioxide run turbine on the horizon and this month engineers from GE Global Research unveiled a turbine that could provide power for 10,000 homes now with the remarkable potential to solve the world’s energy needs.

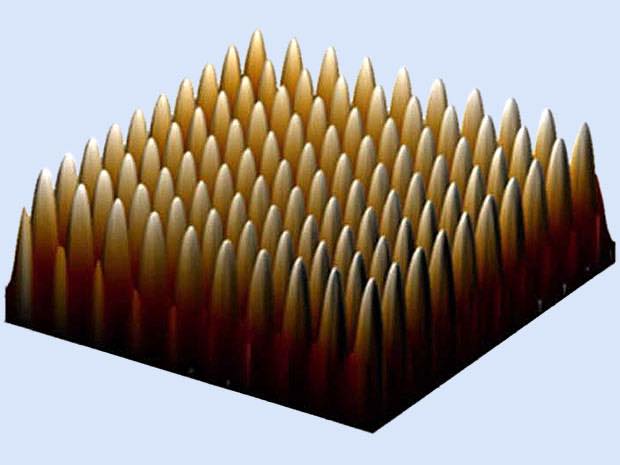

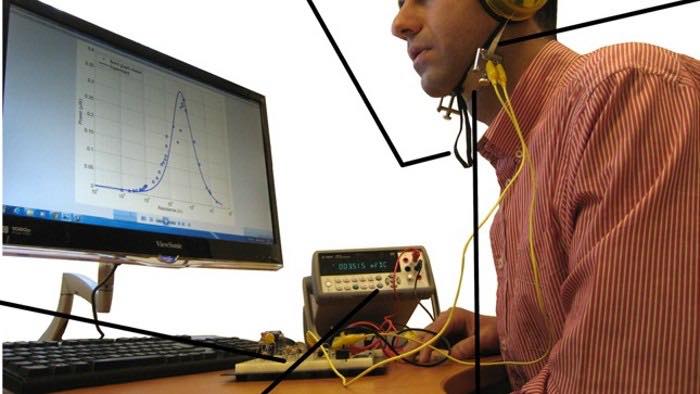

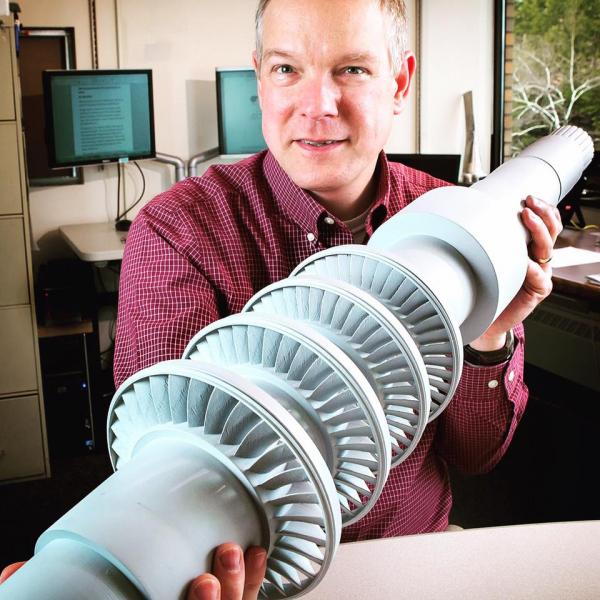

Turbines usually weigh tons and use steam to run—this one, as you can see, is no bigger than the size of your desk, weighs around 68 kg (150 pounds), and runs on carbon dioxide. “This compact machine will allow us to do amazing things,” states Doug Holfer, lead engineer on the project, “the world is seeking cleaner and more efficient ways to generate power. The concepts we are exploring with this machine are helping us address both.”

The current design of the turbine can produce 10,000 kilowatts of energy to be produced; and researchers are hoping to scale up the technology to generate up to 33 megawatts, enough to power a huge area!

The way it works is the carbon dioxide is kept under high heat and extreme pressure. The carbon dioxide then goes into a physical state somewhere in the middle of gas and liquid. The turbine then harnesses the energy, transferring half of the heat to become electricity.The turbines allows for easy operation and can be powered up and turned off easily making it more efficient for grid storage, a major issue for other renewable energy sources.

The power cycle is a "closed loop" process, that means that the carbon dioxide circulates continuously, ensuring that there are no waste products. To break this down a bit more, the unit is driven by “supercritical carbon dioxide,” which is in a state that at very high pressure and up to 700 °C (1290 °F). And once the carbon dioxide passes through the turbine, it's cooled and then repressurized before returning for another pass. The turbine takes only a minute or two to heat up compared to the 30 minutes it takes a steam system.

Here's to hot, fast supercritical carbon dioxide turbine and game changing innovation!

Photo courtesy of GE Global Research.